Sheet metal is one of the most essential material used in almost all applications that surround us today they are of different types with different properties making their forming process and uses broad.

Different types of sheet metal forming processes.

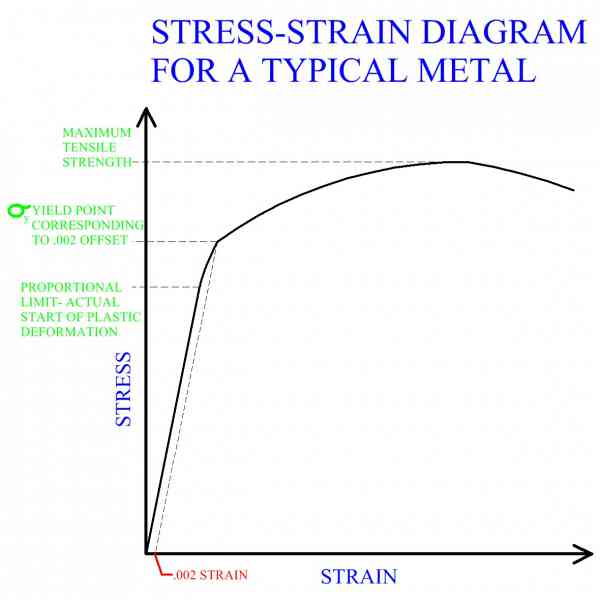

Forming operations cause stress below the sheet metal s ultimate strength resulting in distortion.

Sheet metal forming.

For a process like forging the maximum flow stress value would be very important.

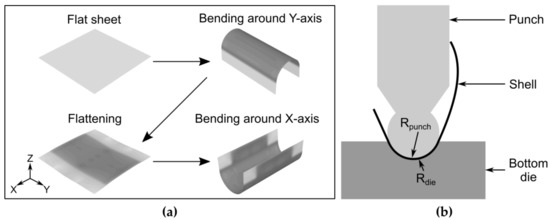

Bending is the process of transforming the straight sheet metal into a curved form.

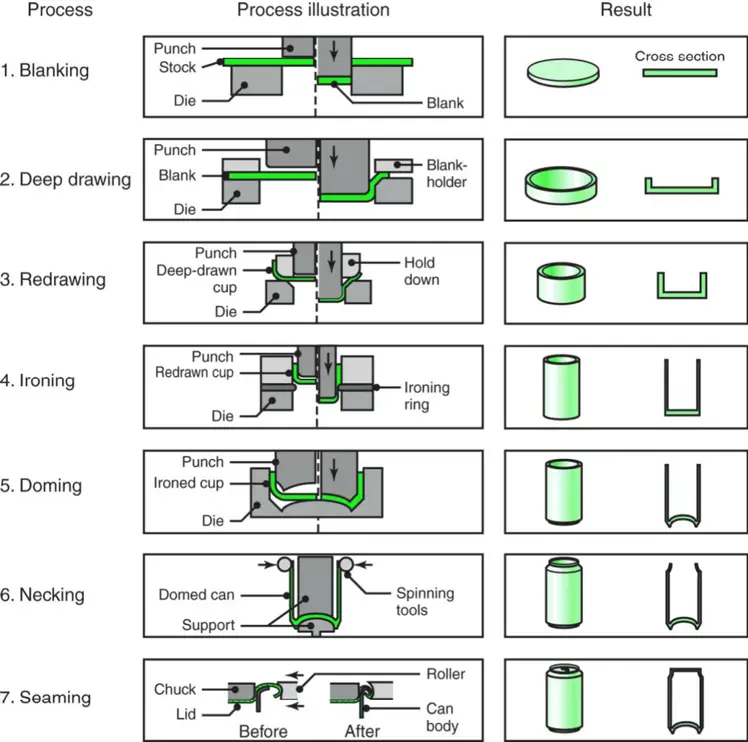

Sheet metal forming process is done on a press and the parts are formed in between two die.

Wiki based upon the manufactured components and the manufacturing process various kinds of forming are developed.

Hu in mechanics of sheet metal forming second edition 2002.

Sheet metal is metal formed by an industrial process into thin flat pieces.

Classification of metal forming processes 3.

The die at the top is called a punch.

There are a number of different types of bending such as.

This is a commonly used manufacturing process that helps in manufacturing the parts for tons of known and unknown purposes.

Sheet metals are seen on automobile and truck lorry bodies medical tables airplane fuselages and wings roofs for buildings architecture and many other applications.

Mainly sheet metal process can be divided into three types.

Techniques of metal forming processes.

And also the below mentioned article provides a lecture note on metal forming processes.

Different types of sheet metal forming processes and their applications and characteristics are discussed below.

Types of metal forming processes 2.

In this article we will discuss about the metal forming processes.

The first one is sheet metal cutting second one is sheet metal bending or forming and the last one is known as deep drawing in this article we mainly focus on sheet metal cutting operations and other two we will discuss into upcoming articles.

Sheet metal is formed cold.

However for a process like extrusion where the metal is continuously being deformed and the different stages of the metal s deformation are occurring simultaneously it.

Extremely thin sheets are considered foil or leaf and pieces thicker than 6 mm 0 25 in are considered.

It can be done in various ways such as forming along the complete bend in a die or by wiping folding or flanging in special machines or sliding the sheet over a radius in a die.

Bending along a straight line is the most common of all sheet forming processes.

Sheet metal forming processes.

Forming is the most widely used sheet metal operation used for manufacturing various sheet metal components across the industry.

Thicknesses can vary significantly.

For different types of metal forming processes the flow stress analysis may be different.